Bearing Damage Index

Fretting

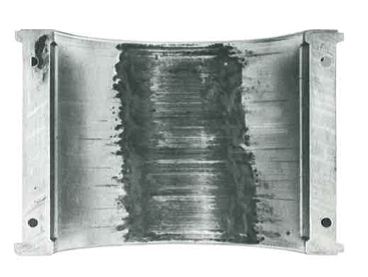

Bearing operating surfaces may suffer fretting damage while the shaft is at rest due to vibrations transmitted to the machine from external sources such as nearby machinery. Shipboard machinery is especially prone to this problem.

If the machine is started up after fretting has occurred, the hard black deposit can cause wiping and obscure the original fretting damage.

Similar damage can occur to machines in transit if the shaft is not clamped.

Addressing the Damage

If feasible, flexibly mount the affected machine to eliminate the transmission of vibration from external sources. If this is not possible, circulating oil through the bearings of the stationary machine can reduce the amount of damage.

In cases where damage is occurring in transit, clamp the rotor to prevent vibration during shipment.

Figure 1: Surface damage caused by external rotation while the shaft was not rotating

Figure 2: Pad pivot showing hemispherical cavities caused by pivot fretting due to vibration