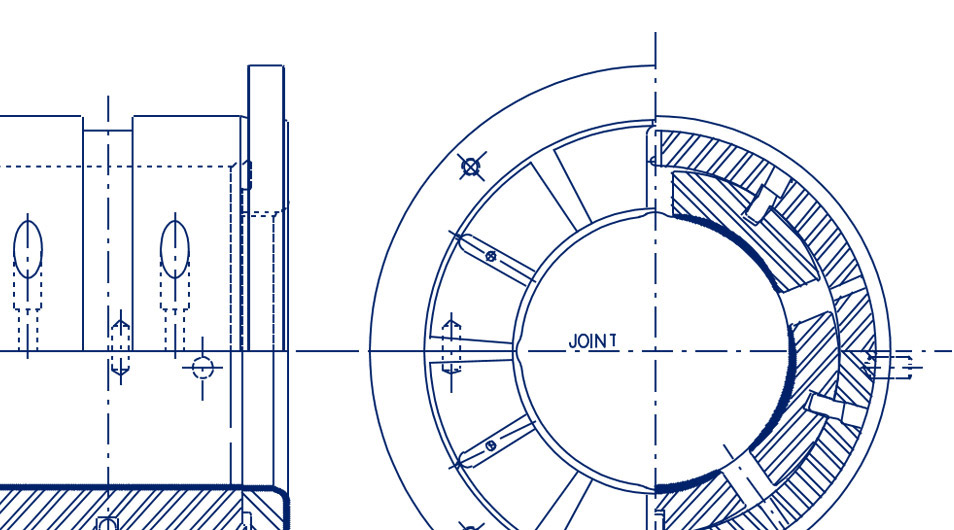

Fixed Profile Bearings

For applications with relatively good stability and low loads, Bearings Plus provides a range of fixed profile geometries for journal and thrust bearings.

Bearings Plus sets the standard for the engineering, manufacturing and repair of fluid film bearings and sealing solutions. Our product portfolio is expertly applied to improve efficiency and service life of rotating equipment across the oil & gas, power generation and industrial markets.

Bearings Plus offers a complete line of hydrodynamic fluid film bearings. Journal and thrust bearings are available in fixed profile and tilt pad designs, including rocker back, ball and socket, and our optimum performance Flexure Pivot® tilt pad. In addition, our patented ISFD® technology – an integral squeeze film damper – is available to increase dynamic stability.

With a variety of proven designs, bearing sizes ranging from 7 mm (0.3″) to more than 910 mm (36″), and years of experience supplying critical applications, Bearings Plus can design and manufacture a bearing solution to your exact specifications.

Bearings Plus fixed geometry and compliant sealing systems are applied to the full range of rotating equipment, including gas turbines, steam turbines, compressors, pumps, turbo-expanders, and electric machinery.

By providing the industry with high-quality seals, BPI has improved efficiency and solved rotordynamic vibration problems in countless machines for end users and OEMs.