Flexure Pivot Tilt Pad Thrust Bearings

Reduce Power Loss, Extend Bearing Life

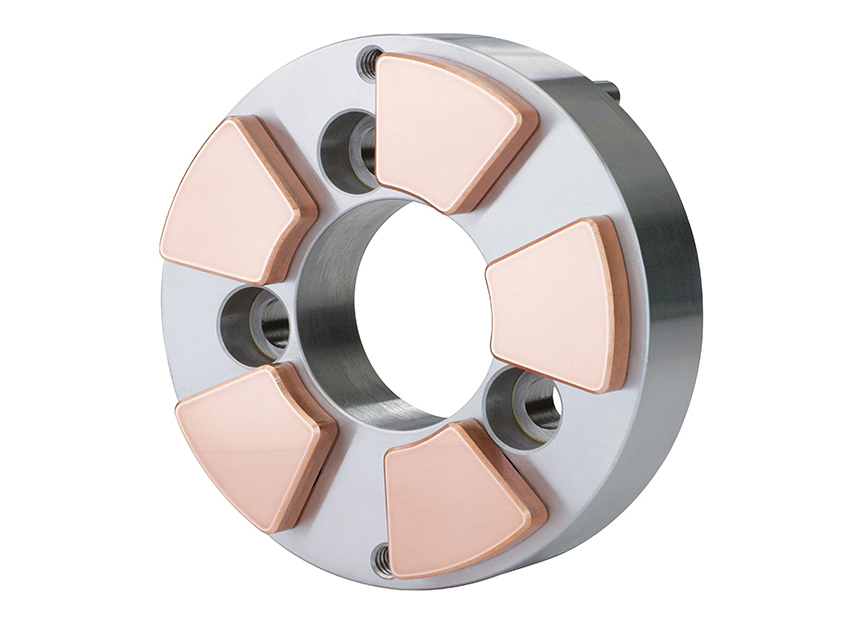

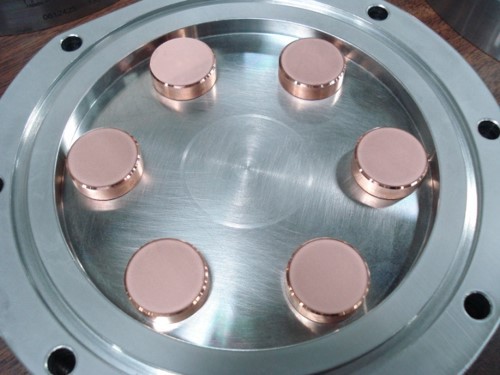

Flexure Pivot® tilt pad thrust bearings reduce power loss and extend bearing life over a wide range of speeds, loads and temperatures. Ideal for retrofit due to their space-saving design, these specialized fluid film bearings increase load capacity, accommodate misalignment and reduce pivot wear.

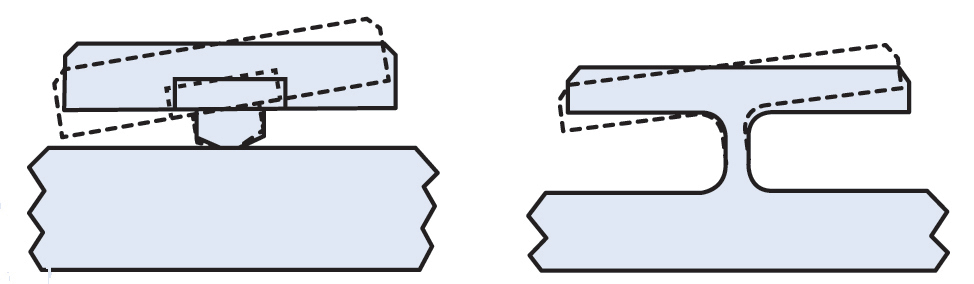

Flexure Pivot tilt pad thrust bearings form a wedge through flexure of the post support, eliminating the pivot wear and high contact stresses associated with point or line contact tilt pad bearings.

The custom design of the Flexure Pivot post support to each application provides the optimum wedge ratio at the design load conditions, resulting in greater load capacity and a significant reduction in power loss. Offset Flexure Pivot tilt pad thrust bearings can also carry higher loads in reverse rotation than conventional tilt pad bearings, giving them an additional benefit in certain high-load applications.

Address Common Challenges

The rotational stiffness provided by the Flexure Pivot thrust bearing eliminates the pad flutter often experienced on the unloaded side of conventional tilt pad thrust bearings. In addition, the Flexure Pivot design provides some amount of axial compliance for forgiveness of static and dynamic misalignment.

Special surface preparation and material selection allow Flexure Pivot bearings to carry higher loads at lower oil flow rates, making them a bearing of choice for applications where lubricant availability is low.

Retrofit Capability

Due to the space-saving pad design, Flexure Pivot thrust bearings can be retrofit in small spaces where only taper land or flat thrust plates would typically fit. This design flexibility allows load capacity upgrades without the need for housing modifications.

Since Flexure Pivot bearings contain fewer parts than conventional tilt pad bearings, installation, inspection and maintenance are also much simpler.

Technical Data

- One-piece or split configuration

- Typical sizes from 25 mm (1″) to 300 mm (12″)

- Compact design for retrofit

- Surface speeds up to 200 m/sec (650 ft/sec)

- Unit loads up to 4 MPa (580 psi)

- Range of material options:

- Babbitted surface with steel/copper alloy backing

- Non-babitted copper alloy (CrCu, BeCu)

- Polymer surface with steel backing

- Instrumentation – RTD or thermocouple temperature sensors

Typical Applications

- Integrally geared air/process compressors

- Refrigeration compressors

- Integrally geared pumps

- Micro gas turbines

- Expanders

- Gearboxes

Downloads

- Flexure Pivot Bearings Information Sheet

- Experience in the Use of Flexure Pivot Tilt Pad Bearings in Boiler Feedwater Pumps

- Design, Analysis and Testing of High Performance Bearings in a High Speed Integrally Geared Compressor

- A Flexible Pad Bearing System for a High Speed Centrifugal Compressor

- Thrust Bearing Inquiry Sheet