Utility Steam Turbine Brush Seals

Engineered for Rotordynamic Performance

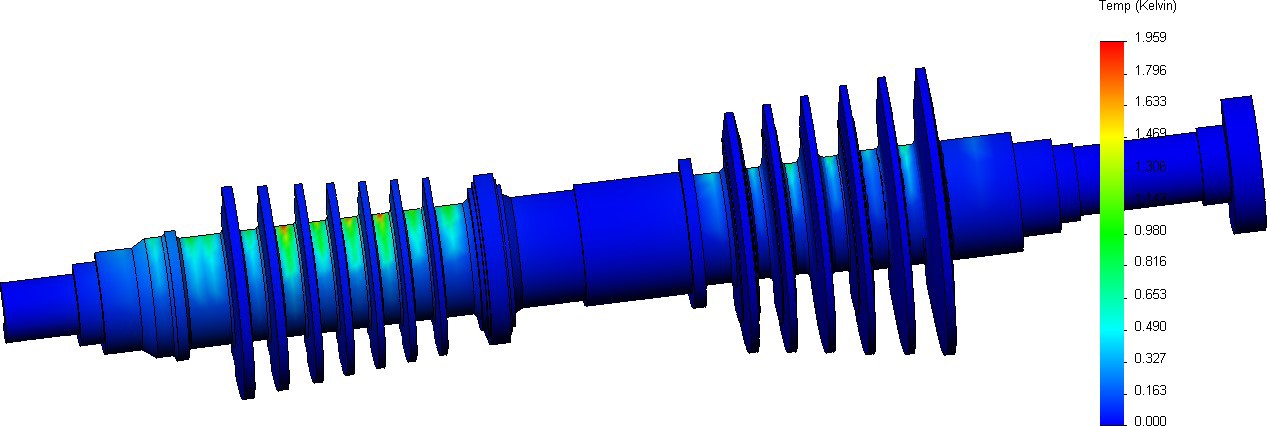

Large utility steam turbines pose one of the most challenging applications for implementing a brush seal.

These machines often require a system-level engineering approach that includes evaluation of the rotor-bearing system dynamics, rotor system heat stability, structural integrity of components, brush seal performance, startup and shutdown performance, and compact installation concepts.

The engineering experience and breadth of in-house analytical tools at Bearings Plus enable us to provide comprehensive engineering studies to tackle these challenging applications.

Brush Seal Application

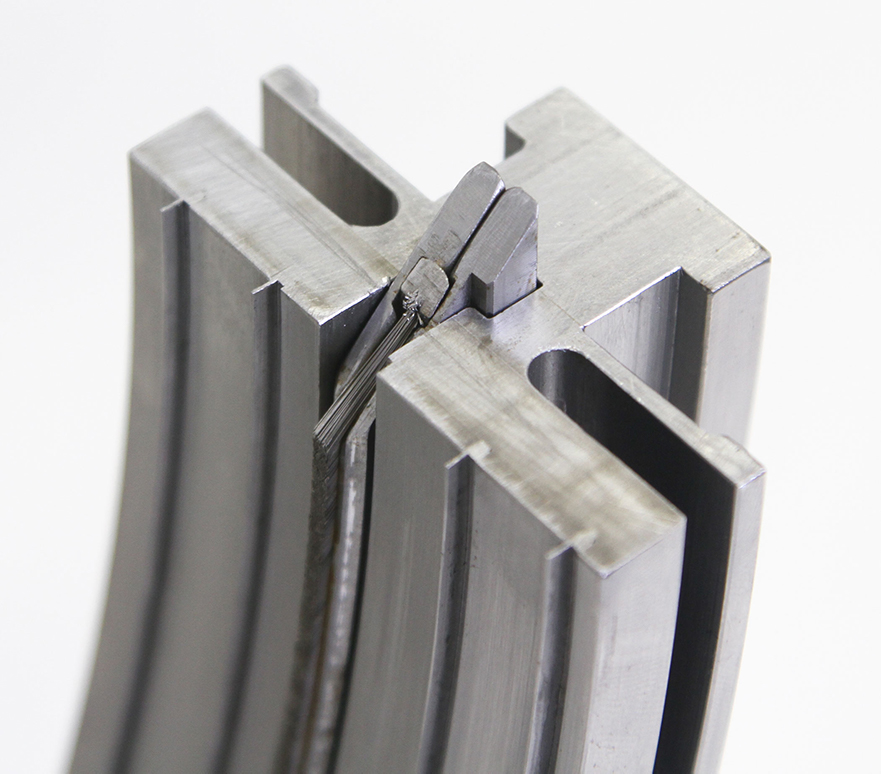

Commonly, three locations of brush seal implementation are considered in utility steam turbines:

- End-packing seals

- Interstage shaft seals

- Turbine bucket tip seals

Downloads

Rotordynamic Analysis

Rotordynamic analysis evaluates bearing and seal characteristics simultaneously to better understand the independent effect of each component.