Honeycomb Damper Seals

Honeycomb seals feature precisely machined, tightly packed individual chambers to create pressure drop and prevent gas swirl.

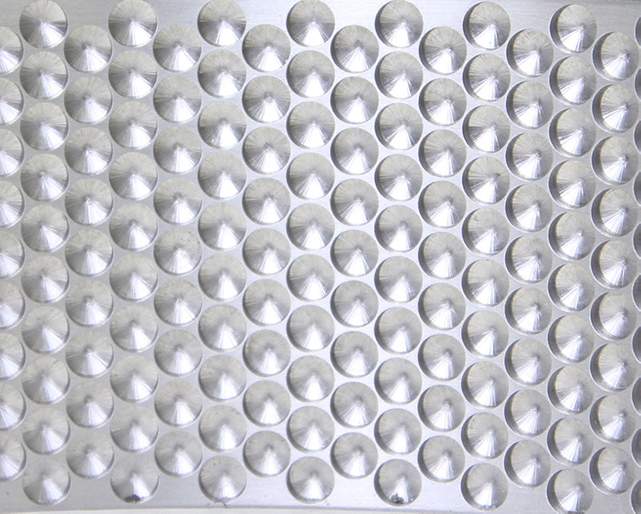

Hole pattern seals work on a principle similar to the honeycomb seal. They were developed in an effort to simplify the manufacturing process for honeycomb seals.

Like the honeycomb seal, the hole pattern seal geometry and design is optimized and analyzed using a bulk-flow engineering program. Oftentimes these seals are packaged with a swirl break to further enhance the effective damping and minimize the location of the effective damping cross-over frequency.