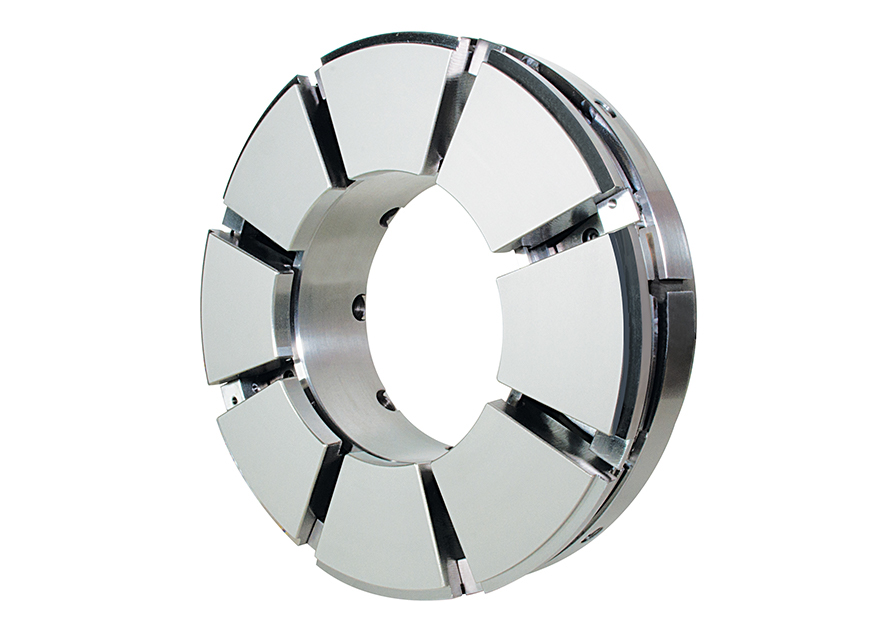

Ball and Socket Thrust Bearings

Ball and socket thrust bearings from Bearings Plus reduce pivot wear and contact stresses typically associated with tilt pad bearings.

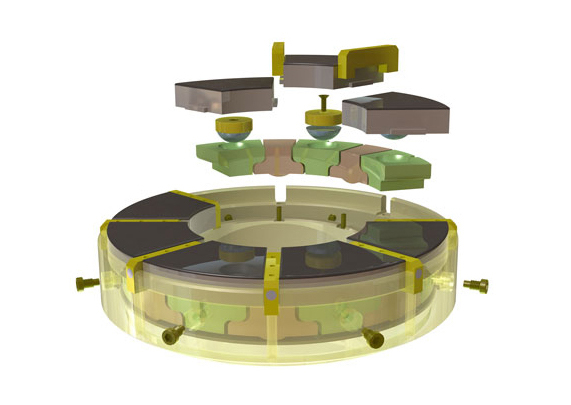

The full surface contact of the ball and socket pivot reduce stresses while providing the necessary stiffness and misalignment capability. Our ball and socket thrust pads are part of a self-equalizing design that ensures even loading across the thrust assembly.

Design Options

Ball and socket thrust bearings are available with flooded, evacuated or ‘Directed’ lubrication. With ‘Directed Lubrication’, oil is supplied at the leading edge of each pad through nozzle blocks, reducing oil flow, power loss and bearing surface temperatures, particularly at high speeds.

The ball and socket material depends upon the application needs and can include steel and babbitt, copper and babbitt, or polymer surfaces.

Technical Data

- One-piece or split configuration

- Typical sizes from 50 mm (2″) to 450 mm (18″)

- Surface speeds up to 135 m/sec (450 ft/sec)

- Unit loads up to 4 MPa (580 psi)

- Materials – babbitted surface with steel/copper alloy backing

- Instrumentation – RTD or thermocouple temperature sensors

Typical Applications

- Integrally geared/process compressors

- Pumps

- Motors

- Turbines

- Expanders

- Gearboxes